Abstract

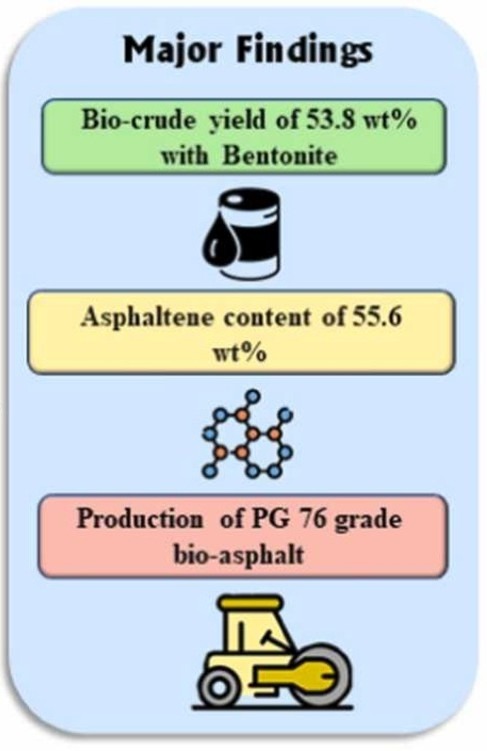

Road transportation is still a prominent communication system in today’s high-tech world, leading to heavy usage of petroleum-based asphalt, consequently worsening environmental pollution. On top of that, improper management of fecal sludge (FS), a significant wet waste, leads to greenhouse gas (GHG) emissions and global warming. In this study, we took the opportunity to convert fecal sludge (FS) into asphaltene-rich bio-crude through hydrothermal liquefaction (HTL) in the presence of low-cost natural clay catalysts (kaolin, bentonite, dolomitic limestone, Netrokona, and Khulna clay). The results showed a maximum bio-crude yield of 54 wt% with a heating value of 34.2 MJ/kg for bentonite clay with asphaltene content of around 56 wt% at 300 °C and 60 min retention time. The highest percentage (61.5 %) of the hydrocarbon fraction from GC-MS indicates the decarboxylation of long-chain fatty acids, indicating asphaltene-rich bio-crude. Similarly, TGA reports around 55 % residue fraction at 600 °C in bio-crude, suggesting a higher asphaltene content. The bio-asphalt exhibited better deformation resistance and rheological behavior regarding complex shear modulus (G*) and phase angle (δ) compared to performance graded 58–28 asphalt binder and 50-grade bitumen. Based on the rutting factor (G*/sinδ) value of 1.42 kPa at 76 °C, the bio-asphalt could be categorized as a high-temperature 76-grade binder, indicating rutting resistance competence at high-temperature paving applications. The study reveals that bentonite clay is a highly effective catalyst for producing asphaltene-rich bio-crude using HTL, offering an economical and environment-friendly substitute for petrocrude and petro-based asphalt towards a green energy production pathway.